Selected Chronicles

1931 Ransomes & Rapier 36/40-ton Breakdown Crane

LMS No. MP3

A brief history by David Withers

Acknowledging the considerable assistance received from railway historian Peter Tatlow, with thanks also to 1970s Holbeck relief BDV foreman Les Woad and crane driver Peter Woad.Allocations and Identities

This crane was built with a 36-ton lifting capacity in 1931 by Ransomes & Rapier Ltd at Waterside Works, Ipswich, to their Order D2958 for the London, Midland & Scottish Railway. Costing around £5600, it was allocated to Kentish Town, London, and shortly after given the LMS number ‘MP3’ (Motive Power No. 3). It was uprated to 40 tons capacity in 1939 and moved to Leeds Holbeck where it remained for the next four decades.

MP3 prepares to lift the 19-ton boiler from BR Standard 5 loco 73050 in Wansford yard, 2003

MP3 received further identification changes during its life. In May 1941, the LMS introduced a new designation system under which the crane became known as RS1004/40 (from Rail, Steam, sequential number 1004, capacity 40 tons). Under the British Railways re-organisation in 1954 the Holbeck depot moved to the North Eastern Region and the crane was re-numbered 331159 but only the last three digits “159” were displayed.

A further re-organisation in 1967 saw the NE Region abolished and Holbeck moved to the Eastern region where the full number DE331159 was used ("DE" meaning "District: Eastern"), and the CEPS system introduced for on-track plant in 1974 saw it change again to ADRR95207. For simplicity it will be referred to hereafter by its original LMS identification MP3.

On 20th June 1978, MP3 (correctly ‘ADRR95207’) attended a derailment at Dearne Valley with assistance from Healey Mills and their 45-ton crane ADRC95224, Doncaster coming in from the south with Cambridge's 45-ton crane ADRC95219. That was probably the final duty for MP3 operating out of Holbeck as Healey Mills was doing Holbeck's work the following week. Healey Mills took over Holbeck's area formally on 31st July 1978 and MP3 was transferred to Doncaster for storage as a spare. The Outdoor Machinery Dept (ODM) took over the Holbeck workshops which became a crane repair depot for permanent way and breakdown cranes.

MP3, the last steam breakdown crane on the Eastern Region, was officially withdrawn in 1979. However a "final duty" was found for it as a stand-in for Doncaster's 75-tonner ADRC96709 whilst this was in Derby Works for conversion from steam to diesel-hydraulic. MP3 was in fact to be maintained in working order at Doncaster for another three years, the diesel conversions taking a while to become reliable.

In December 1982, MP3 was sold for scrapping to Wath Skip Hire of Bolton on Dearne (10 miles to the west of Doncaster) and was promptly resold to the Nene Valley Railway where, after transport by rail to Peterborough, it was put into immediate use. It remains at the NVR and is in frequent operation for mechanical and civil engineering department lifts as well as educational demonstrations and photographic charters.

Though the crane was officially given the number ADRR95207 under the CEPS series, it never carried that number. The reason was that its very last heavy overhaul and repaint in BR days was completed in Derby works on 6th February 1974, just prior to the introduction of TOPS/CEPS.

Why did the LMS need this crane?

Upon its formation under the 1923 Grouping, the LMS inherited twenty-five steam breakdown cranes of which just five were of 35-ton or 36-ton capacity, the majority being 15-ton Cowans Sheldon cranes built between 1893 and 1906. It wasn’t long before the LMS began to build locomotives that were capable of hauling heavy trains without the double-heading that had been frequently practised by one of their major constituents in particular, the former Midland Railway. As the locomotives of the LMS increased in size, their weight went beyond the lifting capabilities of the smaller breakdown cranes even in situations where the cranes could operate in pairs.

From 1923 to 1930, 867 new passenger and freight locomotives of greater than 60 tons were built by the LMS to eighteen classes. The heaviest of these new locomotives was the 152-ton Beyer-Garratt 2-6-6-2T of which 33 were built (Nos. 4967-4999). Other new locos were lighter in weight but greater in number; in particular there were 103 0-8-0 7F Minerals (Nos. 9500-9602) of 61 tons, 190 4-4-0 Compounds (Nos. 900-934 and 1045-1199) of 62 tons and 225 Hughes/Fowler Crabs (Nos. 13000-13224) of 66 tons.

To add to the difficulties brought about by heavier locomotives, the LMS suffered at least eight serious railway accidents between 1923 and 1929, as well as the inevitable minor incidents. It is therefore fair to assume that its cranes saw lots of action and would often have been stretched close to, or even beyond, their formal capacities when lifting the heavier classes of locomotive, the formal capacity being typically 80% of the tested capacity.

Towards the end of the decade the LMS decided that more cranes of 36-ton capacity had to be acquired to deal with heavy breakdowns. It should be noted that, although the term “breakdown” can be taken to mean “accident”, these cranes weren’t used only at scenes of derailment and collision but were also engaged in bridge work, signal gantry erection, crossing replacement and suchlike. However the LMS’s 6-ton and 10-ton travelling engineers’ cranes were preferred for permanent way work as they were less cumbersome and faster.

Six new LMS 36-ton cranes

In May 1930, Derby placed orders for six 36-ton cranes spread between three different builders. Three of these cranes were to be supplied by Cowans Sheldon of Carlisle, two by Craven Brothers of Manchester and the third (MP3) by Ransomes & Rapier of Ipswich. The reason for this diversity of supply has not been established. The basic specification given to the three makers was based very closely on the ex-Midland 36-ton Ransomes & Rapier crane built in 1915 (MP1), this being the first breakdown crane on British railways to have been provided with weight-relieving bogies.

The new Cowans Sheldon and Craven cranes could lift 36 tons out to a radius of 25 feet and 24 feet respectively, however the Ransomes & Rapier could lift the same load out to only 20 feet radius. All six had a working radius from 18 to 40 feet. They were each required to be able to raise the jib from an approximately horizontal position to the working radius, to slew through 360 degrees, and to travel under self-power once at the work site. MP3 was able to travel under its own power at 85 feet/minute (about 1 mile/hour) which was notably slower than the Cowans Sheldon and Craven cranes (150 and 528 feet/minute respectively). Each was limited to 45 miles/hour when being hauled in train formation.

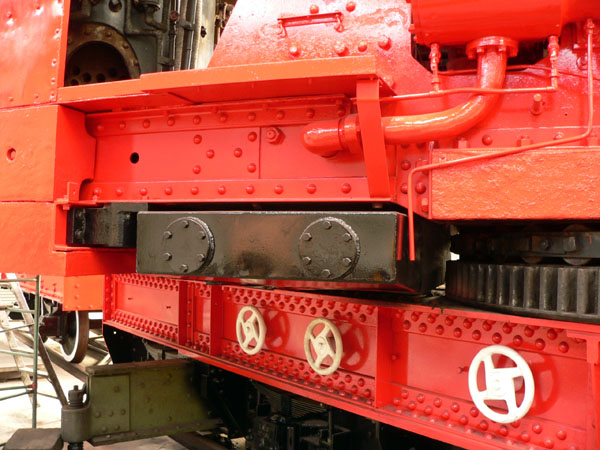

Each of the six new LMS 36-ton cranes was provided with three pairs of propping girders (rigid extending beams sometimes called ‘outriggers’). Three pairs had become the practice on the heavier cranes, however the intermediate girders were soon discovered to be of little benefit on the relatively short four-axle carriages of these new cranes, especially as they were found to take most of the load when all three pairs were deployed. Placing the load on the two outer pairs alone provided sufficient stability because they formed a near-square 17ft x 18ft box enclosing the centroid of mass (which moves both horizontally and vertically during a lift and is also affected by rail cant). The intermediate girders were sometimes used to supplement the outer ones where the ground under the latter was suspect, but this was not good practice. They could also be used on their own for a limited range of lifting but any gain in the setting up time wasn’t sufficient to justify the cost and complication of fitting them and they were omitted from future cranes of the type.

The girders had neither extending ratchets nor screw jacks at their ends, these features being added later, therefore they were hauled out with ropes, with large blocks of wood then being set under the ends and wedged in place.

The six cranes were each delivered complete with two weight-relieving bogies. MP3 had ‘Stokes bogies’ of the type used on its 1915 predecessor built for the Midland Railway. The Stokes patent of 1904 having by then expired, Cowans Sheldon and Craven provided their own designs of relieving bogies, still using the Stokes principle, and their designs were later taken up by BR and continental builders respectively.

Without the bogies deployed but with the jib rested on the jib runner, these four-axle cranes had an axle loading of about 20 tons. In running order, with the bogies fully loaded, the eight axles of the crane and bogies were each kept below 13 tons loading.

The six new 36-ton cranes provided most, but not all, of the answer to the problem of handling the increased weight of locomotives. A 152-ton Beyer-Garratt would have needed division into three parts to be lifted by the 36-ton cranes, and even then the weight would be too much for a crane working solo, however no record has been found of any Beyer-Garratts being involved in accidents or derailments where lifting was needed. All other LMS locomotives built up to the end of 1930 could more often than not be handled by a 36-ton crane, or by two cranes in tandem if a complete lift was needed, so long as the loco had come to a stop at a point that allowed close positioning for the lift.

Unless a very simple re-railing was called for, of an already upright engine over a very short lateral distance, a derailed tender locomotive would be separated at the drawbar and lifted in two parts. Separation was likely to require cutting with a gas torch, however sudden movement of either part as the coupling was cut through could be lethal and so specially-long cutting torches were brought in to reduce that hazard. Similar hazards existed where train couplings needed release by cutting, including those of the buck-eye type where the nuts would be cut.

36 Tons No Longer Enough

A significant change in locomotive size came about from the appointment of William Stanier to the LMS from the GWR in 1932. Stanier’s locomotives included the Black Five, Jubilee, Princess Royal, Princess Coronation and Duchess classes, several weighing over 100 tons. The 36-ton breakdown cranes were no longer large enough for main line use.

Instead of ordering new cranes of greater capacity, the LMS decided, in conjunction with the crane makers, that the existing three Cowans Sheldon and two Craven 36-ton cranes would be uprated to a capacity of 50 tons at their minimum 18 feet radius, the orders for this work being placed with the makers on 28th August 1938. Concurrent with the uprating work, these five cranes were fitted with screw jacks at the end of their girders and ratcheting mechanisms to extend them.

Uprating the capacity of the three Cowans Sheldon cranes to 50 tons entailed, in the main, increasing the circumference of the hoisting rope from 3½ inches to 4 inches which in turn meant new sheaves, ram’s-horn and rope drum. Craven Brothers had been taken over by Herbert Morris at Loughborough who, instead of increasing the rope circumference of the two Cravens, re-rigged the hoisting tackle from four-part to six-part and added two more sheaves at the jib head.

It is likely that the uprating of the five Cowans Sheldon and Craven cranes to 50 tons shortly before the outbreak of World War II precluded the need for the LMS to order new 45-ton cranes to cope with envisaged war damage. Later in the war, the LMS was permitted to purchase eleven 30-ton cranes to undertake work beyond the capabilities of the old 15-ton cranes.

The five 50-ton Cowans Sheldon and Craven steam cranes became the front-runners for dealing with breakdowns and were placed strategically along the West Coast main line so as to be available to deal with any incident involving Stanier’s Pacifics. They were the highest capacity cranes in main line use until British Railways introduced 75-ton steam cranes in 1961.

MP9, Craven Bros 36/50-ton crane for the LMS, preserved at KWVR

MP10, Cowans Sheldon 36/50-ton crane for the LMS, preserved at Didcot

Ransomes & Rapier Crane Uprating

MP3 was uprated in capacity at the same time as the Cowans Sheldon and Craven cranes but to only 40 tons rather than 50 tons, likewise its 1915 forerunner MP1. In the event it seems that no physical uprating was carried out to MP1 or MP3, rather it was a case of formalising the lifting of 40 tons that was undoubtedly being practised anyway but with this higher capacity restricted to the crane’s minimum working radius of 18 feet, with 36 tons remaining the maximum allowed at a radius of 20 feet as before. No record has been found of any extra counterweight being added for the 1939 uprating and the weight of 92 tons recorded for the crane (without jib runner) after the uprating exactly matches that shown on Ransomes & Rapier drawing 53611 of 22/1/1931. As with the Cowans Sheldon and Craven cranes, the girders were fitted with extending ratchets and screw jacks concurrently with the capacity uprating.

MP3's girders and screws function as crane supports during the 2009/10 general overhaul

Ransomes & Rapier Crane at Work

One of MP3’s early tasks after moving to Leeds Holbeck was to clear up after an accident at Winwick Junction on 16th October 1939 when a double-headed express passenger train, with

4-6-0 Patriot No. 5544 leading, ploughed into the wreckage of a collision between a freight train and a light engine.

Another notable task took place on 21st July 1947 when MP3 was one of four heavy cranes to attend an accident near Polesworth Station on the Western Division four-track main line where a Euston to Liverpool express passenger train hauled by streamlined 4-6-2 No. 6244 ‘King George VI’ had derailed due to defective track. The 14-coach train, of 671 tons total weight and 356 yards in length, came to rest 400 yards from the point of derailment. According to the Ministry of Transport accident report, the track of the Down Fast line required “complete renewal” for 380 yards (rails, chairs and sleepers), likewise the adjacent Up Fast for 200 yards, while the Up Slow line required “a considerable amount of repairs” and the Down Slow was “obstructed by the derailed vehicles”. The accident happened at 10.38 on the 21st July and the cranes were at the site by 15.00 that afternoon. The two Slow lines became available to traffic at 19.00 on the 22nd and the Down Fast was restored to traffic at 02.50 on the 23rd, an interval of just 40 hours.

MP3 continued to be kept busy. In 1968, the Leeds breakdown gang answered 423 call-outs of which 289 required use of the breakdown crane (270 for breakdown work and 19 for other reasons). 69 of the call-outs were to running lines and 354 to yards or sidings.

It is also noteworthy that the crane would often be called upon to lift beyond its formal capacity. It is known to have re-railed, end-by-end, a number of loaded 100-ton oil tankers and at least two Class 37 diesel locomotives "which it did with ease". It also lifted one end of a Class 47 without difficulty but the hoist rope then needed replacing as it finished up with a bend where it passed over the top sheave.

Changes to MP3 from the Original Design

The 1939 uprating of MP3 from 36 tons to 40 tons and the concurrent propping girder modifications have already been described. A number of other changes have been identified as related below:

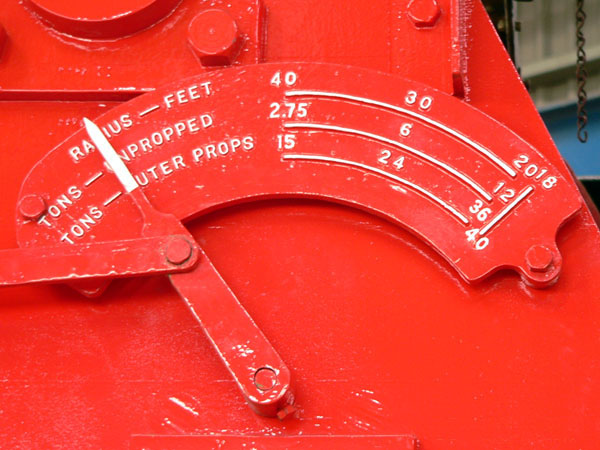

Load/Radius Limits

Evidence has been found of alteration to the load/radius indicators, with the safe working loads at 35 and 40 foot radii, in both propped and unpropped conditions, being reduced by almost 20% from the original limits shown on Ransomes & Rapier drawing 53611 of 22/1/1931. It is possible that the load/radius capabilities were recalculated in 1939 in conjunction with an investigation into the possibility of uprating and that the limits at 35 to 40 feet radius were found to be too liberal.

The original limits at 35 and 40 feet had been ground off all four indicator plates (two cab-mounted and two jib-mounted) and replaced with revised limits marked very feintly and scruffily by number-punch. The 36 ton limit at 20 ft radius had also been ground off and replaced with a painted '40', which was in error as the maximum allowable radius at which 40 tons can be lifted is only 18 feet, with 36 tons being the maximum allowed at 20 feet as always.

During renovation, it was decided that the number-punched limits would not be sufficiently visible to the banksman or driver during lifting operations, so have been replaced with painted figures. Further, the 36 ton load limit at 20 feet has been reinstated on all four plates and the 40 ton limit indicated at its correct position of 18 feet on the cab-mounted plates.

Cab-mounted load/radius plate, left hand side, stripped of paint during renovation in 2010

Cab-mounted load/radius plate, left hand side, post-renovation

Jib-mounted load/radius plate, right hand side, pre-renovation

Jib-mounted load/radius plate, right hand side, post-renovation

On stripping the paint from the cab-mounted plates, it was found that a row of load/radius limits for lifting on the “INNER PROPS” (i.e. the intermediate propping girders) had been removed. Removal of all reference to these girders may have been been decided upon because their deployment could be of disadvantage (as mentioned earlier, it was found that when all six were deployed the intermediate girders took the majority of the load). It is of note that the very similar 35-ton crane supplied to the LNER in 1932 (LNER No. 961601, BR No. 330131) had no intermediate girders, neither did any subsequent crane built for home railways. The specification of three girders per side thus appears to have been an historic LMS requisite rather than the crane builder’s stipulation.

Water Tank

The water tank takes the form of a welded steel vessel of inverted ‘T’ shape situated below the footplate. Ransomes & Rapier “preliminary” arrangement drawing 53556 dated 18/9/1930 suggests the well of the tank to be about 50” wide and 12” deep with the bottom clearing the carriage deck by about 2”. On this drawing the steps up to the footplate, on both sides of the crane, have three rungs which overlap the well and partly obscure the rearmost washout hole.

The “final” arrangement drawing 53556/1 dated 9/1/1931 indicates a wider but shallower well, about 55” wide and 10” deep and now with a drain plug in the bottom. The steps up to the footplate are shorter and narrower, now with only two rungs, and are better located but still overlap the well.

The water tank on MP3 as it now stands has a well 40 inches wide with a depth tapering from 10” to 12” and no drain plug. It appears that the well was reduced in width to make room for the two screw jacks that are wound down onto plates on the carriage to support the tail end of the superstructure during travel, these screw jacks being omitted from the original arrangement drawings. The steps, still of only two rungs, now hang clear of the water tank’s well but partly obscure the screw jacks.

Showing the sloping-base water tank. The ladder and tail jack screw have yet to be fitted.

The lack of a drain facility at the lowest point of the tank led, in 2009, to leakage due to corrosion along the ‘tank drained’ water line (this being the surface level of the water that is trapped when the tank is emptied by removal of a side plate). A drain cock is to be fitted as a ‘non-original but necessary’ feature.

Boiler

The original boiler was a Spencer-Hopwood No.14 Squat of 4ft 6in diameter and 7ft 6in height, with an evaporation rate quoted as 1055 lb/hr in ‘normal steaming’ and 1260 lb/hr in ‘hard steaming’ (i.e. with the use of the blower). A larger boiler was fitted during a heavy overhaul in Derby works from 27.7.1973 to 6.2.1974, more probably as a convenient replacement than for any increase in output. This replacement boiler was also a Spencer-Hopwood, serial number 6319 built in 1951. It appears to be their No.16 Squat of 4ft 9in diameter and 8ft 3in height, for which the evaporation rate is 1200 lb/hr in ‘normal steaming’ and 1440 lb/hr in ‘hard steaming’.

Fitting the larger boiler had been a 'gas axe and sledgehammer' job in respect of the roof-frame modifications that were needed to clear it, however this mutilation was made good when the Nene Valley Railway overhauled the crane between 2000 and 2003, during which time the boiler received a new shell and tubes.

Boiler undergoes free-standing steam test before refitting

Newly-clad boiler hoisted ready for refitting into the crane

Crane Carriage Draw Hooks

Ransomes & Rapier crane carriage drawing 53566/1 of 9/10/1930 called for "Draw Hook and Spring" by way of reference to another drawing (un-numbered), however the reference was crossed out and the word "Cancelled" placed against it before issue of the drawing. The crane carriage was thus not fitted with draw hooks but the reason for their deletion is proving elusive. Possibly they were seen as an unnecessary expense as they would not often have been of use, certainly not while the bogies were attached. However the three Cowans Sheldon cranes that were ordered by the LMS in tandem with MP3 had them and they also appeared on most, if not all, subsequent Stokes-type Ransomes & Rapier cranes built for home railways, including the 1940 ‘wartime emergency’ 45-tonners.

Rear view of crane carriage showing square hole for "cancelled" draw hook

Jib Runner

MP3 was built by Ransomes & Rapier in Ipswich but, as with its five Cowans Sheldon and Craven sisters, the jib runner (or "match wagon") was designed and built in Derby. The six jib runners, to LMS drawing 11/230 of 28/1/1931, were of identical design and MP3’s was numbered 299850. The jib-rest bolster was a crude affair with one long cast iron roller supported on an ‘A’ frame, transverse movement of the jib being by skidding.

Moving on several decades, MP3’s LMS jib runner 299850 became fitted with a far better LNER/ER (Eastern Region) bolster comprising a platform topped with rollers upon which sat a trolley able to traverse from side-to-side. The trolley itself carried a pair of co-axial rollers to allow longitudinal movement of the jib.

The LNER/ER jib bolster can just be made out in this atmospheric picture of MP3 attending a DMU derailment at Ilkley on 5th October 1965.

In or shortly before May 1971, MP3 became paired with LNER jib runner DE961652 from the 1932 ex-Cambridge/Stratford 35-ton crane DE330131, the latter crane having been withdrawn in March 1970. This runner carried an old-style LNER bolster as can be seen in the picture below.

MP3 at Holbeck on 10th June 1972, complete with older style LNER bolster

By 1976 the wheel flanges on DE961652 had worn very thin and it was decided that the wheels needed renewing, so on or about 3rd May 1976, the Holbeck crane and its original 1931 runner LMS No. 299850, now with LNER/ER bolster and BR axleboxes, were reunited on an intended temporary basis, the runner having been refurbished in 1975. However no replacement wheels could be found for DE961652 due to their very small diameter, so 299850 remained with the crane thereafter.

More Facts and Figures

MP3 with its two relieving bogies weighs 92 tons in travelling order, with the jib runner of tare weight 9 tons 3 cwt carrying 5 tons 8 cwt of the 9-ton jib and the 13 cwt of the block (20 cwt = 1 ton). The total weight of the crane and jib runner is 108 tons.

Unlike modern mobile cranes where the wheels are raised off the ground and the propping girder take the full weight of the crane and its load, the wheels of steam breakdown cranes always bear a significant part of the overall weight. The load per wheel on MP3, when lifting at 90° to the rails with the four outer girders firmly deployed, ranges from as little as one ton (tail side, with 15 tons on the hook at 40 feet radius) to as much as 13 tons (jib side, with 36 tons on the hook at 20 feet radius). Spring relieving screws (‘axle locks’ in modern crane terminology) are provided to prevent the surprisingly variable wheel load being taken through the springs as this can render the crane unstable as well as damaging the springs and their hangers.

The various motions are driven by a pair of 9” diameter x 14” stroke cylinders via trains of bevel and spur gears brought into play by dog clutches and cone clutches, with the derricking motion including a worm gear drive. Draincocks are provided for each cylinder and for their common supply pipe, and the pistons are a loose fit in the cylinders so as to avoid any water-lock damage that might result from the intermittent operation that is typical of crane work.

The speed of hoisting can be increased for lighter loads by engaging a different set of gears. As supplied, the crane could lift 36 tons at the rate of 10 feet per minute in low gear or 10 tons at 40 feet per minute in high gear, and the jib could be derricked with a suspended load at 6 feet per minute. The 1939 uprating to 40-ton capacity would have had no significant effect on these speeds.

The superstructure can be rotated 360° on the carriage by the slewing gear, one revolution of the superstructure with a 36 ton load taking 1½ minutes. At the site of operation, two ‘clutches’ (in the form of sliding spur gears) can be engaged to drive the centre two axles for self-powered positioning movements.

The jib is raised and lowered by two sets of derricking tackle, each consisting of five parts of 4¼” circumference steel wire rope, with one part from each of the two sets being wound around the derricking drum. The ram’s-horn is hoisted by four parts of 4¼” circumference steel wire rope, one of which is taken to the hoisting drum.

The total length of hoist and derrick rope is 537 feet (hoist rope of 252 feet and derrick rope of 285 feet). The ropes were specified on Ransomes & Rapier drawing 53618 of 23/1/1931 as “90-100 tons Special Improved Patent Steel, 6/37 Construction, Ungalvanised, having an actual Breaking Load of 54.4 tons”.